- Milling (Grain Crushing)

Action: The malted grains (usually barley) are crushed in a mill to break the husks and expose the starch-filled interior (the endosperm).

Goal: To create a “grist” with cracked husks and finely broken endosperm. The husk should remain largely intact as it will serve as a natural filter bed later.

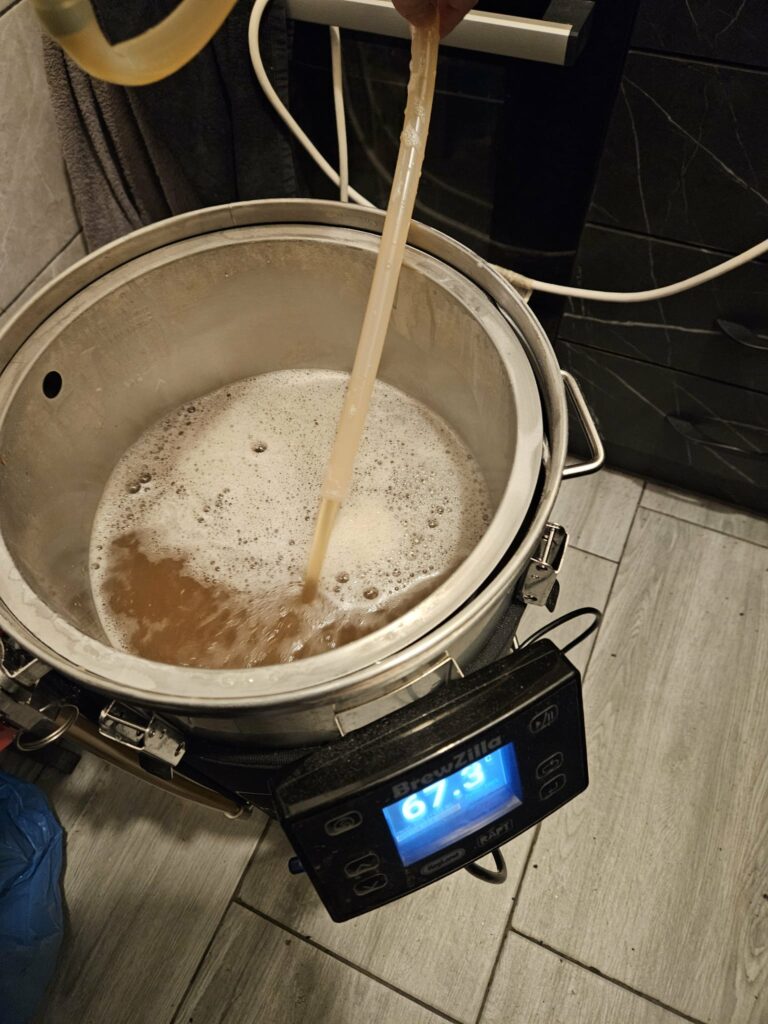

- Mashing

Action: The milled grain (grist) is mixed with hot water (called “liquor”) in a vessel called a mash tun. This mixture is the mash.

Temperature & Time: The mash is held at specific temperatures to activate natural enzymes in the malt, which convert the starch into fermentable sugars.

A common single-infusion mash temperature is typically held between 148°F and 158°F (64°C to 70°C) for 60 to 90 minutes.

Lower temperatures (e.g., 148°F / 64°C) favor enzymes that produce more fermentable sugars, resulting in a drier beer.

Higher temperatures (e.g., 158°F / 70°C) favor enzymes that produce less fermentable sugars (more complex, unfermentable sugars/dextrins), resulting in a fuller-bodied, sweeter beer.

Mash Out: The mash temperature is then raised to about 170°F (77°C) for 10-15 minutes. This stops the enzyme activity and makes the resulting liquid (the wort) less viscous, preparing it for the next step.

- Lautering & Sparging

Action: The sweet liquid, now called wort (pronounced “wert”), is separated from the spent grains.

Lautering: The wort is drained from the mash tun, filtering through the bed of grain husks.

Sparging: Hot water (typically around 170°F / 77°C) is gently sprinkled over the spent grains to rinse out any remaining sugars.

- Boiling

Action: The wort is transferred to the brew kettle and brought to a rolling boil.

Time: The boil typically lasts 60 to 90 minutes.

Goal:

Sterilization: It sanitizes the wort.

Hop Addition (Bittering): Hops are added at the start of the boil (a bittering addition). The high heat causes the hop’s alpha acids to isomerize, which is what creates the beer’s bitterness (measured in IBUs).

Hop Addition (Flavor/Aroma): Hops added later in the boil (e.g., in the last 15-20 minutes or at “flameout” – when the heat is turned off) contribute more flavor and aroma, as their volatile oils are not boiled off.

Concentration: Drives off undesirable volatile compounds, like Dimethyl Sulfide (DMS) precursors.

- Cooling (Chilling)

Action: The hot wort must be cooled rapidly (using a wort chiller) to a specific temperature before yeast is added.

Temperature: Cooled to the yeast’s optimal fermentation temperature, which is highly dependent on the yeast strain and beer style.

Ales: Typically cooled to 65°F to 72°F (18°C to 22°C).

Lagers: Typically cooled to 45°F to 55°F (7°C to 13°C).

- Fermentation & Pitching Yeast

Action: The cooled wort is transferred to a sanitized fermenter, and yeast is added (pitching the yeast).

Time: Primary fermentation usually lasts 5 to 14 days, depending on the yeast, temperature, and beer style.

Process: The yeast consumes the fermentable sugars and produces alcohol, carbon dioxide (CO2), and various flavour/aroma compounds. The temperature must be strictly controlled (according to the desired style) to ensure a clean fermentation profile.

🌿 What is Dry Hopping?

Definition: Dry hopping is the process of adding hops to the beer after the boiling stage, most often during or after primary fermentation, when the beer is cool.

Goal: Its purpose is to impart intense hop aroma and flavour (citrus, pine, tropical fruit, etc.) to the finished beer without significantly increasing the bitterness. Since the beer is no longer boiling, the bittering alpha acids are not isomerized, and the volatile aromatic oils are retained instead of being driven off by heat.

Timing: Hops can be added during the high-activity phase of primary fermentation (where CO2 helps purge oxygen) or once fermentation is complete, typically for 3 to 7 days.

- Conditioning (Maturation)

Action: After primary fermentation, the beer is left to mature. The beer is often cooled (cold crashing) to around 35°F to 40°F (2°C to 4°C) to help the remaining yeast and other solids settle out, which clarifies the beer.

Time: This can last from a few days to several weeks, especially for lagers.

- Packaging (Bottling or Kegging)

Action: The finished beer is transferred to bottles or kegs.

Carbonation: Beer needs CO2 for fizz.

Force Carbonation (Kegging): CO2 is injected directly into the beer in the keg at high pressure.

Bottle Conditioning (Bottling): A small amount of sugar (priming sugar) is added to the beer right before bottling. The beer is then sealed, and the residual yeast consumes this small amount of sugar, creating CO2 within the sealed bottle for natural carbonation.

Time: Bottle-conditioned beer needs to sit at room temperature for 2 to 3 weeks to fully carbonate.